|

Plastics: Empower Medical Device Industry Growth

|

Disposable Medical Supplies world demand is

forecast to expand 6.2 percent annually to $198

billion in 2016. Upgrading and enforcement of

infection prevention standards, coupled with an

expanding volume of hospital, surgical, and outpatient

procedures, will promote overall gains. 10 largest

national markets, combining to absorb nearly 70

percent of global demand in 2016: United States,

China, Japan, Germany, Russia, France, India, Italy,

United Kingdom & Brazil |

|

|

Polymeric Drug Delivery Systems

have wide applications in medicine, are used to

improve therapeutic efficacy and safety of drugs by

delivering them at a rate dictated by the needs of the

body over the period of treatment and to the site of

action, which may reduce size and number of doses,

side effects and biological inactivation and/or

elimination. Controlled release of drugs from a

polymer matrix provides targeted drug delivery,

extension of duration of activity at equal level of

active agent, improved patient compliance, increased

patient comfort, delayed action, reduction of side

effects etc.

Medical Instruments on a global scale accounts for

approximately 43% while Pharmaceutical packaging and

Medical Supplies/Accessories claim second and third

largest portions respectively. |

|

|

For Direct Contact Medical Applications, Special

Polybutylene Terephthalate compounds are

manufactured for direct contact with active

ingredients, are easy to process and moldings made

are dimensionally stable. They feature low sliding

friction. Dimensionally stable housings like

pipette housings and functional components of

inhalers can be made with them. These materials

are also suitable for processing with the

melt-blow process, where the structure of the non-wovens

produced can be adjusted eg: blood filters

|

|

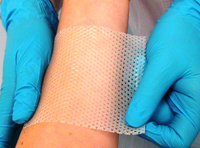

For

Wound Healing, castor oil, absorbent cotton

wool, soft paraffin impregnated gauze are used

from ancient times and still in use. Synthetic

polymeric wound dressings such as silicones,

polyurethanes, polyvinyl chloride or polyethylene

have made their appearance. They are generally

thin layer films which have a synthetic adhesive

as a coating on the inner surface that adheres

well to dry skin at the wound margins but does not

adhere to the wound site. An advantage is that

antibacterial agents such as iodine can be

incorporated into the membranes. Natural polymers

such as collagen, fibrin, fibronectin, alginate

and hyaluronic acid have been studied as dressings

for dermal wounds. |

Though Polymer Based Products Have Been In Use

In Dentistry for quite some time, with the

advent of Bisphenol AGlycidyl methacrylate (BIS-GMA),

more and more innovative products are coming into

the market. BIS-GMA based chemical and light cured

restorative materials, bonding agents, pit and

fissure sealants are widely used for dental

filling applications and for tooth build-up.

Currently the dental market constitutes generally

35-40% of the total medical device market. It is

estimated that India loses about Rs. 1360 crores

every year through foreign exchange towards import

of dental products. |

|

Page

1 :

2 :

3 :

4 |