|

Packaging Testing for Medical Devices

|

Mr. Bunty Kundnani

Business Manager

Life and Health Science,

UL India Pvt. Ltd. Mumbai |

Introduction Medical

Device Packaging is highly regulated and must meet the standard requirement.

Historically devices have been tested for degradation by accelerated aging

and other various material characteristics. Packaging testing is measuring

the characteristics and property of packing material. Most precarious factor

is the sterility which should be maintained through the distribution and

storage. Packaging must comply with ISO 11607 and EN 868-1, in order to

satisfy European regulations and obtain a CE Mark. Testing a new packaging

design before full scale manufacturing can save time and money. Many

manufacture conduct packaging testing in-house or through third party lab

(ISO/IEC 17025 accredited) which is accredited and certified (ISTA

certified, ISO 17025). The testing is vital to ensure integrity of the

package's seal. The general factors that influence the product stability are

physical, chemical, microbiological and toxicological. Most of the

manufacturer conducts the testing at different phases of product life cycle

like product design stage, product launch, and new package design, resolve

package damage issue and sometimes based on client requirement.

Regulations and Standards for Packaging Testing

Packaging testing guidelines are listed in ISO 11607

describing the available ASTM packaging tests. The key aspects of packaging

validation are material qualification, seal validation process and whole

package seal integrity. Physical tests like burst, peal, creep and leak

tests are performed as per ASTM standards. ISO 11607 require both

accelerated and real time aging to be performed simultaneously. The key

areas to be focused in the packaging are stability, performance, package

integrity and strength testing (Figure 1). |

Figure 1 : Package validation testing with Standard Reference Regulations and

Standards

| Package Validation Testing |

| Package Integrity Testing |

Distribution Simulation Testing |

Stability Testing |

Test Procedures :

Seal Intefrity

- Visual inspection (ASTM F1929)

Seal Strength

- Peel Test (ASTM F18)

- Burst Test (ASTM F 1140)

- Bubble Test (ASTM F 2066)

Microblel Challenge

- ASTM F1603 |

Test Procedures :

Atmosphere Conditioning (ASTM D4332)

Drop Test (ASTM D5276)

Vibration Test (ASTM D4728)

Compression Test (ASTM D642)

Low Pressure (ASTM D6653) |

Test Procedures :

Accelerated Aging (ASTM F 1980) |

Package Integrity Test

Depending on package design, a variety of package integrity testing methods may

be employed. This is to ensure the integrity of package seal and system. Visual

inspection, peel strength, burst strength, creeps and bubble emission test are

some of the package integrity test. During the study conduct deformities break

or crack, blister can be observed (Figure 2).

|

Figure 2 : Deformities from visual inspection.

|

Seal strength test is conducted through a simple burst

and / or creep test where packages are pressurized and evaluated for the

rupture pressure points and time of failure. It is conducted to measure the

ability of package seal to resist separation. Burst and creep testing

entails pressurizing the inside of the package and measuring the pressure

required to either cause seals to separate or packaging materials to

rupture. Some packages use porous materials, allowing the contents to be gas

sterilized through the porous package walls after the package has been

sealed; burst testing of these packages can require higher inflow capability

in order to achieve sufficient pressure to challenge the package. |

| Figure 3 : Burst test (ASTM F1140)

|

Dye penetration test is conducted to detect the presence

of any leakage in the seal, (Figure 4). This test method is limited to porus

material which can retain the dye penetrant solution and prevent it from

discoloring the seal for 5 seconds. The study can be conducted through

different methods like injection, edge dip and eye dropper. |

| Figure 4 : Dye penetration

|

Bubble test as per ASTM F2096 standard is conducted by

visually inspecting for bubble streams caused due to affect in the packaging

while it is submerged in water. This destructive testing provides a

practical way to examine packages for gross leaks, which may render the

product non-sterile. This test may apply to very large or long packages,

which do not fit into any other package integrity test method apparatus. |

| Figure 5 : Bubble Test

|

Peel Testing is performed in accordance with ASTM F88 and EN 868-5Standard

Method for Seal Strength of Flexible Barrier Materials. The test results are not

only related to package integrity, but also to measuring the packaging

processes' ability to produce consistent seals. Given that seal strength is a

necessary requirement for packaging, Peel Tests are ubiquitous for all types of

packaging.

Transport Simulation

The medical packages encounter many variables during the transit from the

manufacturing site to the sterilization facility, distribution center, health

care facility, etc.

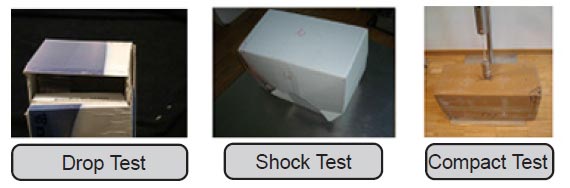

Distribution Simulation is large and quintessential component that complies with

the standard and are of three types (Figure 4);Drop test, Vibration test and

Compression test. It is necessary to expose the packages and products to

atmospheric conditioning in order to simulate particular field conditions that a

packaged product or component may encounter during its expected life cycle. |

| Figure 6 : Transport Simulation

|

Drop test study is used to determine the package ruggedness nature and interior

cushioning effectiveness when the products/packages systems are exposed to bumpy

situation during material handling operations.

Vibration study as per ASTM D999 & ASTM D4728is used to determine the package

withstand to the stresses, shock and vibration that will be encountered during

the transit and package's ability to function and protect in real world

conditions.

Compression study as per ASTM D642 is to determine the maximum resistance of

compression and lock term stacking strength of the packages (Figure 7). For

example, foam is compressed to deine how well it maintains its cushioning

properties. |

| Figure 7 : Study results

|

Stability Testing/ Shelf Life Testing

Accelerated Aging is a testing method used to estimate the product lifespan when

actual data is unavailable or have not gone through the entire product lifespan

cycle. A product can be released to market based upon successful Accelerated

Aging of the package/product that simulates the period claimed for product

expiration (1 year, 2 years, etc). Accelerated Aging data is recognized by

regulatory bodies as an acceptable means to generate data quickly, but is only

accepted until those tests can be repeated on "real time" samples.

Accelerated Aging test is carried out by subjecting the product to unusually

high levels of stress (rapid, but controlled, changes in temperature, humidity,

pressure, strain, etc.) designed to mimic the effects of normal use.

Real-Time Aging provides the actual data to determine shelf life and the effects

of aging on materials. |

Conclusion

In packaging medical products that impact lives and health, the costs of poor

quality control can be enormous. In todays fast moving global markets, the

stakes are higher than ever. As competition and time pressures have grown, the

industry and its regulator shave come to recognize that traditional testing

method scan be slow and potentially risky. Package integrity testing has been

acknowledged to be an important tool for ensuring the safety of package systems

and the products they protect. UL testing and validation services are based on

ISO 11607-1:2006 and ASTM standards are designed to assure compliance with FDA,

ISO, EN and CE Mark requirements. UL can support the non active medical device

manufacturers with Biocompatibility testing as per ISO 10993, Materials

Characterization, Microbiological testing, Virological testing, Physico-Chemical

analysis, Shelf Life of devices and packages, Transport safety and Tes of

Ophthalmic devices.

References

1. ISO 11607-1:2006, Packaging for Terminally Sterilized Medical Devices; Part

1: Requirements for Materials, Sterile Barrier Systems and Packaging Systems

2. ASTM D999 08, Standard Test Methods for Vibration Testing of Shipping

Containers |