|

|

Compatibility of Thermoplastic Polyurethanes

with Drugs for IV Sets

Ms. Elena Draganoiu, Global Technology Manager,

Lubrizol LifeSiences, USA.

Yolanda Zhu1, Clark Yan1, Wei-bo Qiu1, Hong Zhang2, Elena Draganoiu3

1Lubrizol LifeSciences, Lubrizol Specialty Chemicals Co., Ltd., Shanghai,

China,

2Institute of Chemistry Research, China National Science Academy, Beijing,

China,

3Lubrizol LifeSciences, Lubrizol Advanced Materials, Inc., Cleveland, OH,

USA |

Introduction

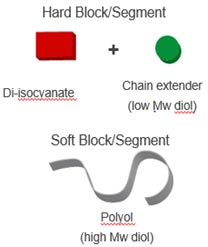

Thermoplastic polyurethanes(TPU) are formed by step-growth polymerization

between di-isocyanates and diols. Polymeric diol and isocyanate groups aggregate

to form a two phase domain structure consisting of :

- Soft segments (low Tg) - contribute to the elasticity / flexibility

- Hard segments (urethane) form crystalline domains and physical crosslinks due

to hydrogen bonding; they confers mechanical strength

TPU schematic structure

|

|

TPUs have a long history of proven biocompatibility and

in vivo stability in biomedical applications, including cardiovascular

(central venous catheters, heart pacemaker connectors, cardiac assist pump

bladders, tubing, housing, coatings, lead insulators, vascular grafts,

patches, percutaneous shunts), urology (catheters, hemodialysis tubing,

membranes), orthopedics (orthopedic splints, bone adhesives), wound care,

etc.

Pellethane® TPUs produced by Lubrizol LifeSciencesare

aromatic polyether and polyester TPUs available in natural color and in a

wide range of durometers. Specially developed extrusion and molding grades

allow ease of use with existing equipment and minimal modifications.

Pellethane® TPUs are widely used for a variety of medical applications

including tubing, catheters and implants due to their attributes: |

• Excellent biostability and biocompatibility

• Outstanding hydrolysis resistance and non-hemolytic properties

• Plasticizer free

• Good compression strength, excellent kink resistance, flexibility and softness

• Superior clarity

• Greater strength with good flexibility compared to PVC, allowing thinner wall

tubes ab fluid storage bags with enhanced burst resistance

• Easily incinerated, no corrosive or dangerous chemical emissions

• Manufactured on world class ISO 9001:2008 facilities

The use of thermoplastic polyurethanes for intravascular (IV) sets has seen a

recent increase, however comprehensive testing to evaluate their compatibility

with drugs has not been conducted prior to this study.

Compatibility between medications and intravascular administration sets

(containers, tubing, and delivery) is important for administration of prescribed

medications to assure predictable delivery of the drug dose, safety and

efficacy. Potential interactions between drugs and IV sets include:

Sorption

• Adsorption of the active pharmaceutical ingredient (API) to the inner

surface (without further penetration) results in initial reduction in drug

concentration delivered to the patient and as the surface become saturated,

concentration restores

• Absorption of the API into the material. The drug concentration in the

infusate is initially low and slowly recovers as the material becomes saturated

• Permeation - drug migrates through the material and out onto the outer

surface of the IV set. Substantial drug loss that continues throughout the

duration of administration

• Leaching - components of IV sets (plastics) migrate to drug

• Polymer modification - drug modifies properties of the IV set (polymer)

The purpose of this study was to evaluate in vitro compatibility of IV sets

of thermoplastic polyurethanes with an array of drugs with different properties.

Methodology

Three types of infusions sets (manufactured by Jiangsu Suyun Medical Materials

Co., Ltd., China) were tested :

• Thermoplastic polyurethane set made from Pellethane® TPU

• Styrene butadiene thermoplastic elastomer set (TPE)

• Polyvinyl chloride (PVC) set (standard PVC with diethylhexyl phthalate)

All sets had similar tube design: OD 4 mm,ID 2.4mm, length 1.6m (Fig. 1-3).

Fig. 1. TPU IV set Fig.

2. TPE IV set Fig.

3. PVC IV set

The study included seven common IV drugs, to cover different properties (aqueous

solubility and log P) and therapeutic classes as shown in also tested. The study

parameters (drug dose, volume, concentration, flow rate, administration time)

were designed to simulate clinical administration (Table 1).

The concentration of drug in the solution circulated through the IV sets was

quantified at different time intervals by high performance liquid chromatography

with UV detection, using reference standards. The impurity level, pH of the

solution and particulates were measured before and after circulation in the IV

sets. IV sets based on TPE and PVC were also evaluated for comparison. |