|

Better Hearing Thanks To

Laser Welding

Phonak

Hearing Aid

The

development of hearing aids has been facilitated by the

incorporation of laser welding using the mask welding

concept. It is necessary to provide protection in the area

of the sound outlet in order to guarantee reliable

functioning of hearing aids that are getting ever smaller

and which are worn within the ear. In the novel «SmartGuard»

cerumen protection concept by Phonak, a highly elastic,

extremely thin diaphragm is welded onto a small carrier

ring. The mask welding process, developed and patented by

Leister Technologies, enables this high-precision joining

process providing protection from contamination. The

development of hearing aids has been facilitated by the

incorporation of laser welding using the mask welding

concept. It is necessary to provide protection in the area

of the sound outlet in order to guarantee reliable

functioning of hearing aids that are getting ever smaller

and which are worn within the ear. In the novel «SmartGuard»

cerumen protection concept by Phonak, a highly elastic,

extremely thin diaphragm is welded onto a small carrier

ring. The mask welding process, developed and patented by

Leister Technologies, enables this high-precision joining

process providing protection from contamination.

Difficulty of

hearing and reduced hearing capability is widespread. In

many cases these conditions can be alleviated to a large

degree using modern hearing aids.

Continuous

development of hearing aids also leads to miniaturisation,

with the aim of providing the user with smaller, more

comfortable and virtually invisible hearing aids. There

are different types of hearing aids which differ in their

shape: so-called BTE (behind the ear) hearing aids and the

considerably smaller ITE (in the ear) hearing aids. In

addition to the technical differences, the ITE hearing

aids primarily have the optical advantage that, depending

upon the shape, they are virtually invisible from the

outside.

A big problem

with all hearing aids is the contamination of the sound

outlet by ear wax in the auditory channel, the so-called

cerumen. The loudspeaker – also called the earpiece – is

located deep within the ear channel, particularly in the

case of the ITE hearing aids. In order to ensure long term

functioning, this must be effectively protected from

contamination and moisture. The demands on such protection

are high. In addition to the acoustic properties,

strength, durability and media resistance as well as

consistent high quality of sound play a significant role.

The Swiss

hearing aid specialist Phonak has a turnover of more than

a billion Swiss Francs and a global market share of 16 to

17% and is thus one of the leading hearing aid

manufacturers in the world. Phonak is constantly making

new innovations that make a considerable contribution to

the society.

Leister

collaborated with Phonak to Laser weld cerumen

protectors on Phonak hearing aids.

The

improvement in quality of life of people with hearing

damage is beyond imagination. One of these innovations is

the new cerumen protector «SmartGuard». This uses a 15 µm

(micron) thick polymer diaphragm to protect the sound

outlet from cerumen and moisture, without having any

significant deleterious effect on the acoustic properties.

The diaphragm is mounted on a thermoplastic carrier ring.

The strength of the connection to the carrier ring is

high, despite the small area of the joint. Any deposits on

the diaphragm can be removed by regular wiping with a soft

cloth. This does not damage the diaphragm or the

connection to the carrier ring, thus ensuring a long

working life for the cerumen protector.

Laser welding

also means that the necessary media resistance of the

joint is achieved. The recommended period of use of two

months exceeds the period of use of the existing

fabric-based protection systems. After this period of use,

the cerumen protection can easily be replaced using a

special tool.

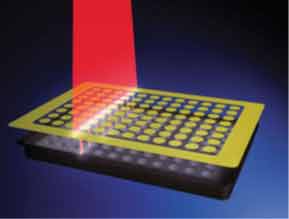

Mask

Welding

The mask

welding process – developed and patented by the Swiss

laser system manufacturer Leister Process Technologies and

operating on the principle of laser transmission welding –

is used for joining the diaphragm to the carrier ring.

This involves connecting a joining partner that is

transparent to laser radiation with an absorbing joining

partner.

In the case

of the cerumen protection, the diaphragm is transparent to

laser radiation. The carrier ring, on the other hand, is

made from a thermoplastic material which has a fixed

shape. It is black in colour and thus absorbs the laser

radiation. In the mask welding process used here, a mask

is inserted between the laser source (diode laser) and the

component. A linear, well collimated – in other words,

parallel – laser beam is moved over the parts to be

joined.

The laser

radiation only impinges on the parts to be joined that are

not blocked off by the mask. The use of the mask makes it

possible to illustrate the finest of structures. This

means that mask welding can achieve high levels of

precision. This welding concept allows fulfilling a

further requirement, namely the need to keep the area for

welding to a minimum. This means that there is more area

available for the acoustically active diaphragm surface.

It is only with the mask welding process that the

necessary strength can be achieved with the smallest of

welding areas. A further significant advantage is the

minimal weld pool depth. The formation of a weld bead can

be virtually eliminated. This, in turn, has advantages

with regard to dimensional reproducibility and acoustics.

Phonak

evaluated various joining processes for this demanding

application. The requirements for welding consisted, in

general, of the resistance to mechanical and chemical

activity. Laser welding had the following advantages when

compared with the other processes: No pre-treatment of the

surfaces, such as plasma irradiation or priming (chemical

activation of the surfaces) is required. These would have

a negative effect on the foil. Joining processes which

produce melting would not be acceptable because of space

restrictions.

The high

level of reproducibility associated with mask welding has

proven to be an advantage over joining processes involving

the application of additional materials.

In addition

to the process-technological reasons, mask welding also

has economic advantages. The consumption of supplies is

regarded to be low, when compared with other processes.

Batch processing processes, which are carried out

semi-automatically and which can be run on plants such as

the NOVOLAS WS allow volumes of several millions to be

produced in a year. Not least is the advantage that the

joining process is even more economical because of the

lack of additional material consumption.

Prospects

Because of

the properties already referred to, the mask welding

process is particularly suited to applications in medical

technology. In this way foils can be welded onto micro

well plates without the melt flowing into the apertures.

Mask welding is also recommended for fluidics in general –

and for micro fluidic components in particular. This

precise and cost-effective process finds applications in

products for the entertainment electronics and computer

peripherals.

Another

process developed by Leister is radial welding. In this

process, rotationally-symmetrical parts are welded

together without having to move with respect to the laser.

In medical technology this process is used for welding

catheter attachments. Radial welding also finds

applications in sensor technology, fluidics and in the

automotive engineering.

The GLOBO

welding process, patented by Leister, also finds

applications in medical technology. It allows dynamic

pressing together of the joining parts, and, for example,

it allows two transparent foils to be welded together. The

heat energy is transferred to the foils by an absorbent

black substrate [which has a melting point which is higher

than that of the parts to be joined together]. This

concept can be used to join large area components and

endless applications.

Success

Story, No 2/08 / ENG © Copyright by Leister India

Headquarters : Leister Technologies India Pvt Ltd No.

4/27B, Kambar Street, Alandur, Chennai 600016 phone: +91

44 45583436,

info@leister.in Leister Technologies AG is an ISO 9001

certified enterprise.

|