|

Quality Requirements For

Medical Textiles, PPES / Face Masks

|

K. R. Navaneethakrishnan, MSc, ERT

Assistant Director,

GLR Laboratories Private Limited, Chennai |

Personal Protective Equipment (PPE)

have become a mandatory part of our life, given the

unforgiving grudge of the global pandemic on the human

race. PPEs play a significant role in preventing

transmission of infectious agents, not only in hospitals,

but also in various activities such as cleaning, waste

management and safe burials, and community care related to

the outbreak. March 2020, saw an incredible increase in

the import of personal protective equipment kits by

various countries which led to a global shortage of

supplies. In India, the PPE industry grew a stunning 56

times in the last couple of months. As many as 600

companies in India are registered to manufacture the

protective gears. |

As per a notification released by MoH &FW

vide S.O. 648(E), PPE kits are considered as a medical device,

in pursuance of sub-clause (iv) of clause (b) of section 3 of

the Drugs and Cosmetics Act, 1940 (23 of 1940). CDSCO

notification dated 03 Sep 2020 listed out 24 devices as

Personal Protective Equipment’s.

Some examples of PPE include :

-

Face shield,

-

Face Mask (Disposable, Surgical, N95),

-

Gowns (surgical gowns, isolation gowns,

surgical isolation gowns, nonsurgical gowns, procedural gowns,

and operating room gowns)

-

Gloves (Latex surgical gloves, Non-latex

surgical gloves, Nitrile gloves, Examination gloves)

With the increase in the demand for PPEs, it is necessary that

manufacturers lay adequate emphasis on the selection of raw

materials as the quality of finished device is heavily

dependent on these raw materials.

Although PPEs are used for personal protection, they

themselves may cause adverse reactions. Adverse reactions that

are commonly reported are acne, skin rash and contact

dermatitis which may arise from some components (adhesives,

rubber straps or metal clips) of the N95 mask. Skin reactions

to gloves included complaints of dry skin, itch, and rash.

Type I immunoglobulin Emediated natural rubber latex

hypersensitivity is an important, often undiagnosed,

occupational health hazard for healthcare workers, especially

in those with high exposure.

Biocompatibility tests (ISO 10993) for

PPE / Medical Textiles

One of the quality parameters that certify

a medical device as safe is its property of being

biocompatible.

Biocompatibility tests are recommended for

medical devices that come into direct contact or indirect

contact with the human body in order to determine the

potential for an unacceptable adverse biological response

resulting from contact of the component materials of the

device with the body. US FDA Guidance document issued on 04

September 2020 states that the term “human body” refers to

either patient tissues or the clinical practitioner. Therefore

"masks or gloves intended for protective purposes by clinical

practitioners should be assessed for biocompatibility."

Testing for biocompatibility considerations

should be performed on the device in its final and finished

form.

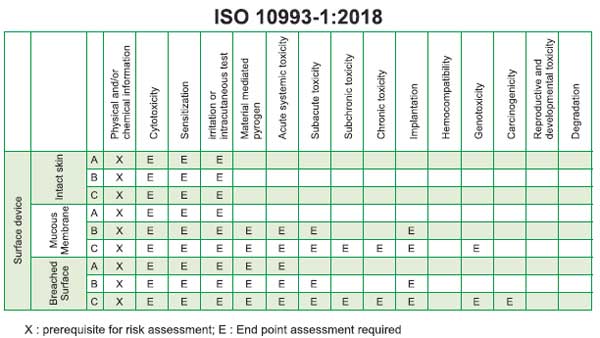

As per ISO 10993-1:2018, majority of PPE

devices are classified as Surface Contacting Devices with

contact duration lesser than 24 hours. Below is a snapshot of

the testing requirements for surface (Skin, Mucous membrane,

Breached/compromised surfaces) contacting medical devices

based on their contact surface and the following

biocompatibility tests are usually recommended for PPEs. The

principle behind each of these tests and the results they

produce is briefly discussed below:

• Cytotoxicity test (ISO 10993-5:2009)

• Irritation/ Intracutaneous reactivity test (ISO

10993-10:2010)

• Sensitization test (ISO 10993-10:2010)

|

|

|

Advertisers' Index

|

|

Accuprec Research Labs Pvt. Ltd., India |

|

Ambica Medicare Engineering, India |

|

Nu-Vu Conair Pvt. Ltd., India |

|

Divya Steri Solutions Pvt. Ltd., India |

|

ET Elastomer Technik, Germany |

|

Eewa Engineering Co. Pvt. Ltd., India |

|

Ineos Styrolution India Ltd., India |

|

I-Kare Polyalloys Pvt. Ltd., India |

|

KLJ

Group, India |

|

Lubrizol Advanced Materials India Pvt.

Ltd. |

|

Kuraray India Pvt. Ltd., India |

|

Maider Medical Industry Equipment Ltd.China |

|

Medicall 2019, India |

|

Ferromatik Milacron India Pvt. Ltd., India |

|

GLR Laboratories

Pvt. Ltd., India |

|

Pashiba Lifescience, India |

|

Plastivision India |

|

Pradeep Surgipack, India |

|

PVC Colouring Compounding & Processing,

India |

|

Qosina,

USA |

|

Raumedic AG |

|

SMC Medical Manufacturing Pvt. Ltd.,

India |

|

Sterimed Medical Devices (P) Ltd., India |

|

Steri Techno Fab, India |

|

Tekni-Plex India Pvt. Ltd., India |

|

Twist Engineering Works,India |

|

Yuhuan Shengjiu Mould Co., Ltd.,

China |

|

Airways Surgical Pvt. Ltd., India |

|

Alpha Medicare and Devices Ltd., India |

|

Alpha Therapeutics Pvt. Ltd., India |

|

Ami

Polymer Pvt. Ltd., India |

|

Angiplast Pvt. Ltd., India |

|

Appasamy Associates, India |

|

Beacon Plastics, India |

|

Delux Surgical, Inida |

|

Ignisol Mediplas Corporation, India |

|

Jain Rubbers Pvt. Ltd., India |

|

Operon Strategist, India |

|

R.R. Patel Gases (P) Ltd., India |

|

Proven Trade Contacts, India

|

|

Sanidhya

Enterprise, India |

|

Surgi Pack India Pvt. Ltd. |

|

Unikal Consultants, India |

|

Vinit Performance Polymers Pvt. Ltd., India |

|

Aircity, India |

|

Amigo Surgi Care

Pvt. Ltd., India |

|

Angel Products, India |

|

Apex Medical Devices, India |

|

Jimit Medico Surgicals Pvt. Ltd. |

|

Kavya Packaging, India |

|

Life-O-Line Technologist, India |

|

Mesco Surgical, India |

|

Morrisons

Lifecare Pvt. Ltd., India |

|

National Healthcare, India |

|

Pharmadocx, Inida |

|

S. Nath & Co., India |

|

Unikal Consultants, India |

|

Venus

Industries,India, Mobile : 9825747495 |

|

Zinkal Products, India |

|