|

Chemical Characterization of Polymeric Medical

Devices: Unveiling the Identity and Risks

|

Dr. Renjith S.

Scientist B, Biomedical Technology Wing,

Sree Chitra Tirunal Institute for Medical Sciences

and Technology, Trivandrum |

Polymeric medical devices

play an inevitable role in day-to-day medical care. We

can observe materials of polymeric origin in a wide

range of medical devices viz. injection syringes,

blood bags, intra-ocular lenses, vascular grafts,

hernia patches, facial implants, catheters, personal

protective equipment (PPE), and many more (Fig. 1).

Every medical device has to undergo strenuous

biological evaluations in line with international

standards to ensure patient safety and avoid undue

health risks. Chemical characterization plays a vital

role in the biological evaluation as well as

toxicological risk assessment of medical devices.

Fig. 1. Representative polymeric

medical devices

Material selection is one

of the first and foremost steps in the development of

medical devices. One should ensure that the material

is fit enough with all the necessary properties and

characteristics encompassing physical, chemical,

mechanical, morphological, electrical, and biological

to be used for the device development. Chemical

characterization enables to ascertain the presence or

absence of necessary properties and also helps to

establish the equivalence of a material with an

established biomaterial. Even though chemical

characterization alone wouldn’t give a complete

evaluation of a medical device; along with

toxicological risk assessment it would enable the

screening of potential materials/devices for clinical

applications and, establish the biological safety of

new or reprocessed medical devices. ISO 10993 series

of standards describes the biological evaluation of

medical devices with direct or indirect contact with

patients. ISO 10993-18 lays a framework for the

chemical characterization of medical devices involving

the identification and qualitative and/or quantitative

estimation of medical device components to identify

biological hazards and to estimate and control the

toxicological risks associated with medical devices.

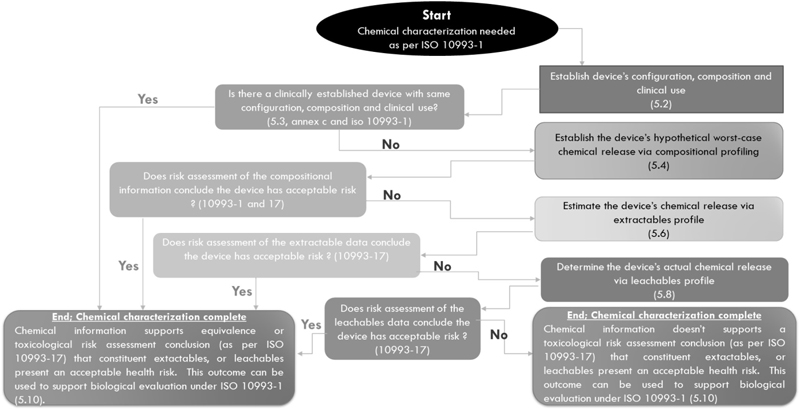

The flow chart of the chemical characterization

process as per ISO 10993-18 is outlined in Fig. 2.

The first step in the

chemical characterization of a medical device is to

identify the materials of construction. It generally

means the identification of the components with which

the medical device is made (medical device

configuration). The components of a medical device can

be of polymeric, metallic, or ceramic origin. The

detailed configuration of the medical device will give

the chemical identity of the components, the physical

forms in which they exist in the device, and their

geometrical distribution in the device. Further, the

composition of the individual components of the

medical device has to be estimated. It includes the

percentage purity of the component along with the

quantity of impurities, process aids, or additives

present in it. Catalytic residues, sterilization

residues, and possible degradation products are also

to be estimated. For establishing the medical device

configuration and composition, the information can be

gathered (from vendors), generated, and augmented by

using various characterization methods. A complete

list of characterization techniques suitable for

medical device configuration and composition is

available in ISO 10993-18.

When the complete picture

of the medical device (device configuration,

constituent composition, and clinical use) is

available, one should check if there’s an equivalent

device. The biological equivalence of two devices or

materials involves a number of terms such as chemical

equivalence, physical equivalence, material

equivalence, and contact equivalence. If two medical

devices have identical device configurations,

constituent compositions, and processing methods, they

can be called chemically equivalent. Medical devices

with identical configuration, morphology, topography,

and tribology are said to be physically equivalent. If

two devices have chemical equivalence and physical

equivalence, they could be said to have material

equivalence. Similarly, two devices with identical

clinical use and endpoints of biological evaluation,

are said to have contact equivalence. For two devices

to be called biologically equivalent, they should

demonstrate material and contact equivalence. If

the preliminary chemical characterization of the

medical device is successful in establishing its

equivalence with an established device, one can stop

the chemical characterization with the conclusion that

the medical device has an acceptable health risk and

this outcome could be used for biological evaluation

as per ISO 10993-1.

Fig. 2 Flow chart of chemical

characterization process as per ISO 10993-18 |