|

The

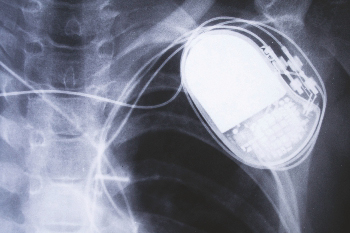

Biocompatibility and Biostability of the Materials

Chosen for Your Device will Affect its Clinical Success.

(Curtsey : Lubrizol)

A material’s biocompatibility and

biostability profile is a critical consideration in the

development of your next medical device. The specific

requirements of the medical device greatly influence the

choice of appropriate material, as biocompatibility and

biostability performance always need to be considered in the

context of the end-use application.

To help ensure positive patient

outcomes and mitigate potential risks when designing your

device, your team should consider numerous factors that

influence device biocompatibility and biostability during the

material selection phase of development. In this overview, we

will highlight the most important factors to help guide you to

success in choosing the right polymer for your device.

THE MOST COMMON FACTORS

AFFECTING BIOCOMPATIBILITY AND BIOSTABILITY -

The biocompatibility and

biostability requirements of a particular medical device are

dependent upon its application-specific design and performance

requirements. For example, the material utilized in a

long-term cardiac implant has a stringent set of

biocompatibility and biostability requirements designed and

tested around extended blood and/ or tissue contact.

Conversely, a temporary surgical application may not consider

biostability as a critical factor due to the limited duration

of use. Below are key application-specific biocompatibility

and biostability factors to consider.

Factor 1: DEVICE LOCATION

The location of use within the

body determines the chemical environment that the material

sees, which in turn influences the material performance

requirements. For example, in direct blood contact, the body’s

immune response (via the white blood cells), can create a

harsh oxidative environment at the material surface as the

white blood cells try to phagocytize (consume) the foreign

material. Therefore, devices in long-term direct blood contact

generally need materials with excellent oxidative resistance.

Conversely, devices in contact with skin may not experience

the same level of oxidative pressure as in blood contact, so

materials with resistance to hydrolysis (degradation by water)

may be appropriate for construction. Furthermore, medical

devices in contact with extreme pH environments, such as in

the gastric system, require materials that can perform under

chemically harsh environments.

Factor 2: DURATION OF DEVICE

CONTACT

A device’s duration of use

determines biostability requirements and can dictate

biocompatibility evaluation endpoints. For example, a

short-term catheter that may only be in the body for several

hours will not be subject to the same evaluation endpoints as

an orthopedic implant designed to perform for years. From a

biostability perspective, the chemical resistance required in

an environment (as described above – oxidative, hydrolytic,

extreme pH, etc.) is dependent on exposure time. Therefore, a

device which needs to remain stable for hours may require

different materials than a device used in the same environment

that needs to remain stable for years. From a biocompatibility

perspective, devices that are in contact with the body for an

extended period will require different biocompatibility

assessments including chronic toxicity, and genotoxicity.

Additionally, potential degradation byproducts and

extractables from the device materials may also need to be

evaluated either via chemical or biological assessment.

Factor 3: MECHANICAL ACTIVITY

AND REQUIREMENTS

The mechanical load to which a

device component will be subjected during use (tension versus

compression or static versus dynamic) can have significant

implications on its biostability. Some polymers under constant

or repetitive strain break down more quickly from biological

conditions than unstrained polymers. For example, the

mechanical requirements of an orthopedic implant are

significantly different than material used in temporary

drainage tubes. In this situation, additional polymer-specific

considerations may need to be specified to ensure proper

performance.

Factor 4: DEVICE CONTACT WITH

DELICATE TISSUE

If the device is contacting

delicate tissue, the mechanical action of the device against

tissue can cause a physical biological response (i.e.

swelling, tearing) that can impact the overall

biocompatibility of the device. In this case, the mechanical

properties of the material are as important as the chemical

compatibility and should be considered during the initial

phases of material selection for a device.

Factor 5: LOCAL EFFECTS AT THE

BIOMATERIAL INTERFACE

Depending on a medical device’s

application, a determination needs to be made as to whether

protein adsorption, fouling, and bacterial adhesion are a

concern. These factors can significantly impact device

performance, and material selection can be tailored based on

the requirements at the biomaterial interface.

Factor 6: DEVICE STERILIZATION

Certain sterilization methods can

change chemical and physical properties of device materials,

potentially impacting their performance, including

biocompatibility and biostability. Some thermoplastic polymers

are negatively impacted by the heat, pressure, and humidity of

autoclave (steam) sterilization methods. In extreme cases,

autoclave sterilization can generate unwanted degradation

byproducts in some polyurethanes. Other methods such as gamma

or e-beam radiation are typically appropriate for

thermoplastic polymers, but selecting an appropriate radiation

dosage can be important to prevent chemical changes to the

device materials.

Factor 7: OVERALL DESIGN AND

MANUFACTURING PROCESSES

Lastly, your team should

holistically consider the design and manufacturing process of

the device. What are the implications of other materials (i.e.

conductive metals) contained in or in contact with the device?

Will any additional chemical additives be required (i.e.

plasticizers)? Will any coatings or textures be applied to the

final version of the device? Will components be thick or thin

walled? What processes will be utilized to manufacture the

components? These design decisions can greatly impact

biocompatibility and biostability of the final product, which

is why it is important to partner with a trusted materials

expert that can help guide you through these questions.

PARTNERS FOR BETTER POLYMER

PERFORMANCE

Lubrizol is equipped with decades

of knowledge and experience to provide OEMs with the insight

to understand how device design and end use will determine

component biocompatibility and biostability requirements and

how this must drive material selection to create a clinically

safe and effective device. For more information contact

Rajnish.Singh@Lubrizol.com;

Mittal.Shah@Lubrizol.com.

|