|

Cold

Plasma Treatment For Biomedical Applications

|

Mrs.

Purvi Dave,

Scientist SC

Facilitation Center for Industrial Plasma

Technologies

Institute for Plasma Research,

Gandhinagar, Gujarat

fcipt@ipr.res.in

www.plasmaindia.com |

We all

have been taught that there are three states of

matter: solid, liquid and gas. The plasma is the

fourth state of matter. In a more simple way, we can

say plasma is an ionized gas. Scientists say that 99%

of universe is in plasma state. If we supply

sufficient energy to gas either in the form of heat or

electricity, electron comes out from the atom or

molecule and thus electrons, ions and reactive gaseous

chemical species are generated. In plasma stateions,

electrons, neutrals, activated gaseous species

coexist. We see natural plasmas around us in the form

of lightening and aurora. Sun and stars are live

example of natural plasma. Examples of common man made

plasmas are fluorescent lights, neon bulbs and plasma

arc, plasma TV etc.. Plasma arc is used for cutting

and welding of thick steel sheets.

Scientists and researchers around the world are

working to develop different plasma technologies for

variety of applications to serve mankind. Plasma state

can be generated in the laboratory. Plasma can be

generally classified broadly as: (i) non-thermal or

cold plasma and (ii) thermal or hot plasma.

Cold

Plasma (a kind of glow discharge) Treatment is very

much useful for surface modification of bio-polymers /

medical plastics. Bio-polymers / medical plastics are

widely used for biomedical applications such as

artificial organs (Prosthetic Materials) and cell

scaffolds. Surface properties of the material play an

important role in determining overall biocompatibility

of the materials because the surface of the materials

will first come into contact with biological

environment. The initial response of the biological

environment to such materials, therefore strongly

depend on the surface properties of the materials.

Thus the modification of the surface of the materials

is the convenient and effective way to create and

develop biomaterials for clinical applications. |

Although many synthetic

biomaterials have physical properties that meet and even

exceed those of natural body tissue, they can often cause

adverse physiological reactions such as infection,

inflammation and thrombosis formation. Through surface

modification, bio-compatibility as well as

bio-functionality can be achieved without changing bulk

properties of the material.

In order to obtain optimal

biological performance, it is usually necessary to apply

surface treatments or coatings to biomaterials. Plasma

treatments are used to incorporate chemically reactive

functional groups on to the polymer surface and thus make

them hydrophilic.

Hydrophilicity plays an

important role in cell and bacteria behaviour.It is

reported that enhancing the surface hydrophilicity by

introducing oxygen containing functional groups such as

hydroxyl (-OH), carbonyl (-COOH), ketone (-C=O) leads to

an increase in cell attachment. It is also reported that

Hydroxyl groups contributes to cell colonization.

It is well known that cell

walls of most bacterial strains are negatively charged.

Therefore more negative surfaces construct an initial

defence line against microbial adhesion by an

electrostatic repulsion. Air plasma treatment can

introduce negatively charged functional groups on the

surface. With increasing concentration of these groups,

the surface becomes more hydrophilic and more negatively

charged. Thereupon due to the strong repulsive forces, the

antibacterial effect increases [Fatemeh et al. Applied

Surface, Science 2015].

Similar type of research

work in the field of surface modification of polymer

surfaces by eco-friendly plasma process is being done at

Facilitation Centre for Industrial Plasma Technologies (FCIPT),

Institute for Plasma Research (IPR). IPR, Gandhinagar is

an Autonomous R & D Institute under the Department of

Atomic Energy (DAE), Government of India situated near

Gandhinagar, Gujarat, India.

FCIPT is a division under IPR,

which mainly focuses on technology development for social

benefits and industries. FCIPT develops plasma based

technologies and commercializes through Technology

Transfer to Industrial Partners.

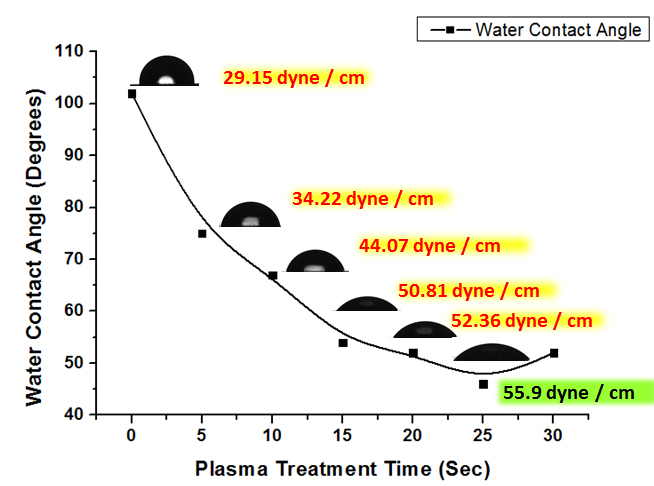

In our study, plasma is

capable of reducing Water Contact Angle (WCA) from 100 ° (WCA

of untreated PE) to as low as 15 ° in the case of low

pressure plasma treatment and 43 ° in the case of

atmospheric pressure plasma treatment. WCA is the measure

of wettability of the material. Polyethylene is one of the

promising medical plastic which is widely used in various

prosthetics in biomedical industries.

At FCIPT, IPR we have

developed plasma surface modification process for polymers

which uses ambient air to produce plasma at atmospheric

pressure. After plasma treatment polymer surface

(Polyethylene, PET, PP) have become hydrophilic in nature,

which is of relevance to biocompatibility. This treatment

can also be done by low pressure air / oxygen plasma.

Below figure shows oxygen plasma generated in our

laboratory.

In

our study, plasma is capable of reducing Water Contact

Angle (WCA) from 100°(WCA of untreated PE) to as low as

15° in the case of low pressure plasma treatment and 43 °

in the case of atmospheric pressure plasma treatment. WCA

is the measure of wettability of the material.

Polyethylene is one of the promising medical plastic which

is widely used in various prosthetics in biomedical

industries. In

our study, plasma is capable of reducing Water Contact

Angle (WCA) from 100°(WCA of untreated PE) to as low as

15° in the case of low pressure plasma treatment and 43 °

in the case of atmospheric pressure plasma treatment. WCA

is the measure of wettability of the material.

Polyethylene is one of the promising medical plastic which

is widely used in various prosthetics in biomedical

industries.

Results of water contact angle

and surface energy after atmospheric pressure air plasma

is shown in figure-2.

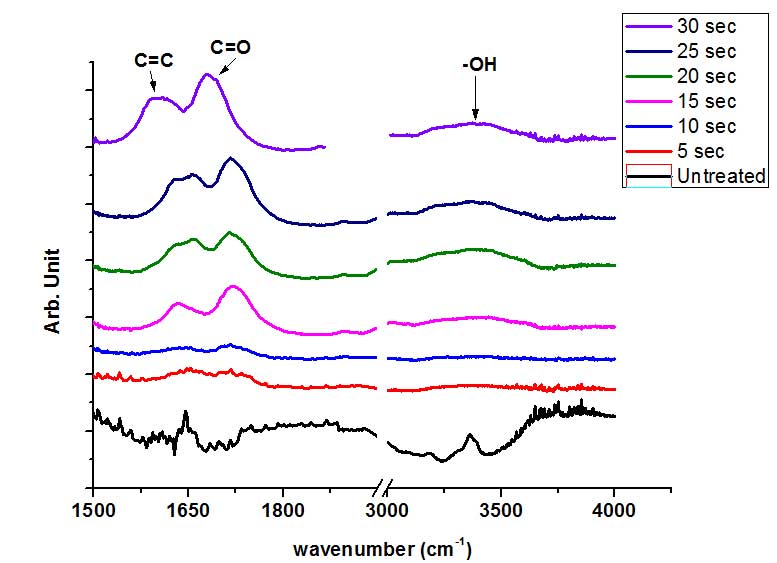

Incorporation of oxygen containing functional groups

after plasma treatment is shown in below figure-3. This

results are FTIR spectrographs.

Another device capable to

form plasma plume is Non Thermal Plasma Torch (NTP).

Recently FCIPT, IPR has developed a compact device NTP. A

plume of plasma comes out of this device. This type of

plasmas is useful for healing skin wounds, blood clotting

in few seconds. The plasma torch is like a small pen which

provides very narrow cold plasma plume which interacts

with skin or blood. Figure below shows view of a finger

exposed to this plasma. Dentists can use this torch for

cleaning cavity in effective manner or for root canal

treatment. The NTP has a potential to use in cancer

therapies as well. Conceptually this device can be

inserted in to lungs with a probe and lung nodules /

metastasis can be exposed for effective treatment. However

this application is yet under evaluation.

FCIPT,

IPR welcomes interested organizations / industries to

contact us at below contact details. FCIPT,

IPR welcomes interested organizations / industries to

contact us at below contact details.

Dr. Nirav Jamnapara

Technology Commercialization Cell

FCIPT, IPR

fcipt@ipr.res.in

www.plasmaindia.com

P:07923269017

FCIPT, IPR has organized one

day workshop on “Applications of Cold Plasma in Surface

Engineering” on September 11, 2015. Registration is Free.

Interested candidates can email us at

fcipt@ipr.res.in to

register. Pre-registration is compulsory. For more details

of this workshop please visit

www.plasmaindia.com

Page :

1 :

2

|