|

Global

Trends in Medical Plastics Technology and Applications

Processing: The

processing of the plastic components is usually done by

standard thermoplastic processing techniques such as

extrusion and injection molding. Other techniques, such as

thermoforming, laser ablation, solvent processing and

silicone rubber processing, may be used depending on the

material and the device requirements.

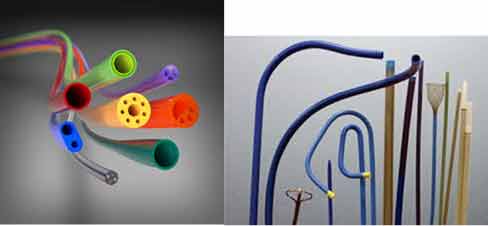

As an example, catheter

extrusion is one of the common devices that are used for a

variety of different devices and purposes. Various

configurations are possible within the extrusion of this

tubing geometry. Catheters with multiple lumens, lumens

with different geometries and curved or straight tubes are

some of the variants in the design, this is illustrated in

Figure 5. Catheter production requires an extrusion line,

water bath, dimensional control, a winder and an annealing

oven.

Figure 7: Various catheter geometries

and shapes

Medical device assembly

is done in a cleanroom. A cleanroom is defined as A room

in which the concentration of airborne particles is

controlled, and which is constructed and used in a manner

to minimize the introduction, generation, and retention of

particles inside the room and in which other relevant

parameters, e.g. temperature, humidity, and pressure, are

controlled as necessary.

The greater the

criticality of the device, the greater the restrictions

placed on the construction of the cleanroom. Medical

plastics, in general, are the components of the device

rather than the device itself and consequently, most of

the medical plastic processing can be done in less

stringent environments.

Sterilization: All

medical devices have to go through the process of

sterilization. Sterilization is the process of killing of

all micro-organisms (bacteria, virus and fungal) by use of

either physical or chemical means. Human skin can never be

completely sterile, hence covering the human skin is an

important aspect of a sterile environment. The inside of

the human body is devoid of bacterial growth and is termed

aseptic. Transfer of germs into an aseptic environment is

contamination Sterilization of all items used in surgery

is essential to the maintenance of asepsis.

There are different

methods of sterilization. The method could be based on

thermal elimination of contamination, either using Dry

heat or Steam. The method could be based on chemical

means, using an Ethylene oxide (ETO) environment, or the

method could be based on the use of high energy radiation.

Conclusion

As the importance of

the use of medical devices in healthcare is increasing,

the worldwide market for these devices is forecast to

increase robustly. Plastics form the core of many medical

devices and therefore the use of plastics in medical

applications is a fast growing market.

Plastics have a great

range of properties and this huge variety of plastics

properties means a number of different medical device

applications can be satisfied by plastics. However, many

times the applications are not fully satisfied as the

properties of the plastic material are not completely

exploited. There is clearly a distinct need for plastics

expertise to be involved in the further development of the

medical field.

The selection of a

particular plastic material is dictated by the needs of

the device and application. Many aspects of the behavior

of the material in different conditions and environments

are taken into account in order to select the right

material.

The production of

plastics components for the medical industry requires

discipline, certain extra procedures and controlled

methods.

Plastics production for

medical applications is, however, not onerous and

difficult.

|