|

High Volume Manufacture Of Thinwall

Medical Device Components

With Liquid Crystal Polymer Thermoplastics

(Courtesy : Celanese Chemicals The Chemistry Inside

InnovationTM)

LCP resins are different but not

difficult. Once their polymer characteristics are

understood, they can be put to good use in pushing the

envelope with advanced

designs, part to part tolerance

repeatability, and high volume productivity in the

tens of millions of units … all with the right design,

tooling and processing.

Liquid Crystal Polymer (LCP)

thermoplastics are well-known in the consumer

electronics industry for tight tolerance designs with

high stiffness and strength, plus rapid cycle times

and extreme flow to fill sub-mm wall sections.

Processing benefits allow for micro-molding and

replication of intricate detail in miniaturized

devices for delivery of therapeutic drugs (biological

and pharmaceutical) and vaccines. These same

advantages are translatable to precision combination

drug delivery devices which incorporate complex

mechanisms and wireless connected electronics for

pharma prescription adherence goals.

Specifically, LCP resins can help

designers and engineers achieve more compact,

intricate components through thin-wall molding even as

low as 0.3mm (0.012in) nominal wall without

sacrificing mechanical stiffness and strength as LCP

polymer chains are inherently stiffer & stronger than

many other neat thermoplastics. This can be an

advantage in wearable/on-body devices where

light-weight, compact form factors add value by

creating more free space for pharma container and

other components which can be critical.

Contents

A. Introduction to use of LCP in Drug Delivery Devices

B. Polymer and processing characteristics of Liquid

Crystal Polymers

C. Design benefits from the use of LCP

D. Case study: Vectra® MT® LCP 1305 Lowers Cost Per

Part And Enables Improved Design For Wearable/On-Body

Injector Chassis

A. Introduction to use of LCP in

Drug Delivery Devices

Miniaturization of drug delivery

devices requires careful planning of the integration

of all components into a compact package. This

miniaturization makes wearable devices lighter-weight,

less intrusive and more comfortable for the patient.

In order to provide information on patient usage for

themselves and their healthcare providers, many drug

delivery devices are integrating electronic circuits

and transceivers, in addition to the mechanical

systems to precisely dose the drug. Special materials

capable of molding small and precise components enable

the design of such complex devices with intricate

designs and thinwalls. These benefits significantly

expand the market for controlled dosing products vs.

conventional self administered injections and provide

reliable and precise delivery outside of a clinical

setting. Production of such

devices at a large volume leads manufacturing to

fast-cycling injection molded plastics with high

cavity tools and hot runner systems. Vectra® MT® LCP

provides advantages for each requirement.

• High stiffness, strength and

toughness with long flow-lengths (>150 mm @ 3.2mm) and

capability for wall thicknesses as thin as 0.3 mm at

common device flow lengths and even thinner with short

flow length.

• Ultra-low viscosity at process temperatures for high

flow in thin wall sections.

• Fast crystallization with small mold temperature

excursions between melt injection and part ejection

for fast cycle times and high productivity.

• Tailored dielectric strength for compact integration

of electronic circuits.

• Inherent V0 UL Flammability rating

These attributes make Vectra® LCP the

preferred material for micro connectors and precision

optics for the miniaturization of consumer electronic

devices such as mobile phone cameras and tablet bus

connectors. Combined with Celanese MT® medical quality

management and service package Vectra® MT® LCP brings

these same benefits to the connected and wearable

medical devices.

B. Polymer and processing

characteristics of Liquid Crystal Polymers

LCP resins are unique in the world of

engineering resins. LCP is a high heat thermoplastic,

but its value for most medical devices is its

exceptional flow in thin-wall designs. The morphology

of LCP resin’s nematic rod-like crystalline structure

is very different from amorphous & semi-crystalline

resins.

Even unfilled LCP is extremely strong

& stiff, behaving like a selfreinforcing polymer,

similar to or exceeding mechanicals of 20- 30% glass

fiber composites.

The nematic structure of LCP helps

with its extremely high flow in thin-wall geometries.

High flow combined with high stiffness & strength

allows designers to make thinner structures without

sacrificing structural performance, enabling smaller

parts & freeing up more internal space for pharma or

other components. LCP flows better under high shear

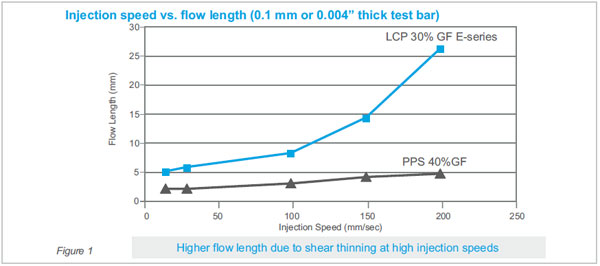

without degrading mechanical properties. Figure 1

shows how LCP flow increases exponentially with high

shear (high injection rate) compared to PPS.

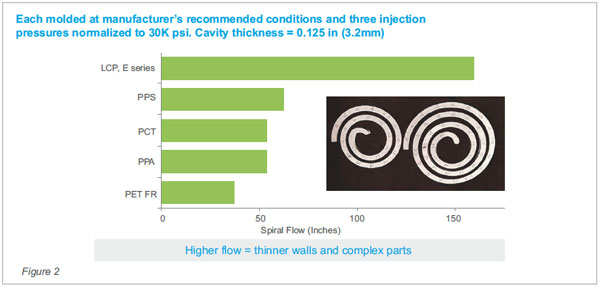

Figure 2 compares spiral flow of 30%GF

LCP vs other 30-40% GF resins at 3.2mm (0.125”).

Each molded at manufacturer’s

recommended conditions and three injection pressures

normalized to 30K psi. Cavity thickness = 0.125 in

(3.2mm)

As seen in Figure 3, LCP has a low

heat of fusion from its ordered molecular structure,

which changes very little from molten to solid phase,

it rapidly solidifies when flow ceases allowing a

rapid cycle from melt injection to part ejection.

Part and tool design must provide for

high enough shear to maintain a low viscosity

throughout the tool. Areas where the flow speed drops,

such as sharp changes in runner direction, can allow

cold slugs to form.

Rapid cycling means more parts per

hour, so fewer molds may be required for high volume

production. Rapid solidification allows for minimal

part flashing. LCP exhibits a melting range rather

than a sharp melt point. The typical solidification

time is a few seconds, with injection molding cycle

time ranges commonly 5 to 15 seconds for small part

molding, depending on the number of cavities.

Since high mechanical shear is used to

thin the resin to make it flow better, high mold

temperatures are not necessary as with polyphenylene

sulfide (PPS) or polyetheretherketone (PEEK). LCP can

be processed at mold temperatures less than 100 °C

similar to many engineering resins and requiring only

water based cooling. Also, contrary to intuition,

smaller gates and thinner runners are better to

increase shear rate and thus flow.

Other characteristics of LCP

include:

• Excellent dimensional stability with

low moisture absorption (0.03%) & low mold shrinkage

(0.1- 0.4%)

• Inherently flame retardant without FR additives

• Very clean, low extractables & ionics, food contact

compliant, biocompatible with MT® grades being FDA

master file listed

• Service temperature from -190 °C up to 240°C, short

term up to 340°C

• High tensile strength (to 185 MPa) & high tensile

modulus (to 30000 Mpa)

• Excellent barrier property to both oxygen and

moisture, one of the best resins

• Sterilizable by steam, ethylene oxide, gamma

radiation or H2O2 plasma

• Excellent chemical resistance

• Natural color is opaque, off-white ivory with

options for coloration.

To support customer applications in

regulated medical devices, Celanese provides

regulatory and quality management support to enable

customer compliance to ISO 13485. This includes

elements related to Celanese polymers, ingredients,

manufacturing controls and supply chain management.

Celanese MT® polymers service

package

• Material compliance to FDA and EU

requirements

• Long-term supply assurance without change of

formulation

• Animal- and latex-free formulations

• Certified biocompatibility (USP 23 Class VI / ISO

10993, etc)

• FDA Drug & Device Master Files |