|

Ethylene Vinyl Acetate

Polymers For Advancing Healthcare

ABSTRACT

Ethylene vinyl acetate (EVA) has a long and successful

history of innovation in medical packaging, medical

devices, and pharmaceutical applications. In fact, EVA

has been an innovative force in those applications for

over 40 years and continues demonstrating its value in

applications presenting everincreasing challenges. New

solutions are required to support continued innovations

that improve patient healthcare.

This article will examine the evolutionary role of EVA

innovation in diverse applications ranging from its

early use in parenteral applications for delivery of

life-saving medications to cryogenic storage bags for

stem cells used in the field of cell therapy.

The molecular architecture of EVA lends itself to the

creation of innovative solutions to some of healthcare’s

most challenging and complex problems. Case studies will

provide an illustration of each of these applications.

INTRODUCTION

We are living at a time when healthcare is undergoing

exciting new developments and innovations. The medical

device industry and the pharmaceutical industry are

developing innovative products which can provide better

patient care and improved quality of life.

Also, and of no surprise, the two industries have

applications in common as well as areas of uniqueness.

For example, an intravenous (IV) bag containing drugs

illustrates where a medical device and pharmaceutical

product work together in support of patient needs. For

an application where a medical device and a

pharmaceutical product work independently of one

another, consider a sleep apnea device versus a tablet

containing an API. Here, the sleep apnea device does not

contain a pharmaceutical product and the tablet is

associated with a medical device.

Ethylene vinyl acetate (EVA) has been used for many

years in both industries and has historically been an

important enabler of innovation. Today and moving into

the future, EVA continues to be an enabling innovation

in established and emerging fields. An overview of EVA

polymers will describe the unique characteristics that

make EVA suited for a range of unique applications in

healthcare.

INTRODUCTION TO EVA POLYMERS

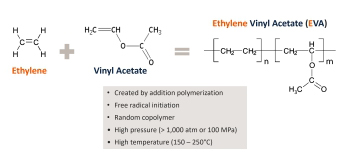

Ethylene vinyl acetate copolymers are made using two

monomers: ethylene and vinyl acetate (VA). The

polymerization may take place by either autoclave or

tubular reactors. Figure 1 illustrates the

polymerization.

Figure 1. Polymerization of EVA

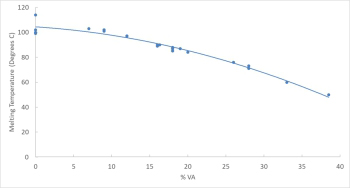

The percent of VA incorporated into the polymer backbone

can vary from 0 to 40. At 0% the polymer is essentially

low-density polyethylene. As VA content is increased,

the polymer becomes more flexible and transparent. EVA

polymers with VA content higher than 40 percent tend to

become a handling challenge from a commercial pelletized

perspective. The melting point of the EVA is influenced

by the vinyl acetate content. As VA content increases,

the melting point decreases. Figure 2 illustrates the

linear relationship.

Figure 2. Melting point versus VA%

EVA has been commercially used for over 40 years in

medical device applications, beginning with medical

tubing. Uses of EVA in healthcare continue to expand, as

the following case studies will demonstrate. |