| DUR/ODR

The method of describing the uniformity of dose in

a given product is the concept of Dose Uniformity

Ratio (DUR), which is the ratio of the maximum

dose in a product container to the minimum dose in

the container. This ratio increases with increase

in the density of the product as well as with the

size of the container/tote box

Validation of radiation

processing

IQ INSTALLATION

QUALIFICATION

OQ OPERATIONAL QUALIFICATION

PQ PERFORMANCE QUALIFICATION

Installation Qualification

Installation qualification is

the process of obtaining and documenting evidence

that equipment (the irradiator and its associated

processing equipment and measurement instruments)

has been provided and installed in accordance with

its specification

Operational Qualification

Operational qualification is

the process of obtaining and documenting evidence

that the installed equipment operates within

specified limits when used in accordance with its

operational procedures. It is carried out after

the commissioning of the facility.

Performance Qualification

Performance qualification is

the process of obtaining and documenting evidence

that the equipment, as installed and operated in

accordance with operational procedures,

consistently performs in accordance with specified

criteria and thereby yields product meeting its

specification

Dosimetry Systems used for

Radiation dose measurement

|

Dosimeter |

Measurement instrument |

Dose

range (kGy) |

Remarks |

| Alanine |

EPR

spectrometer |

0.001-100 |

Various

shapes: rods, pellets |

| Dyed

PMMA |

Visible

spectrophotometer |

1-100 |

1 Χ 3

cm 3 mm thick |

| Ceric-cereous

sulphate solution |

Potentiometer, UV spectrophotometer |

1-100 |

Glass

ampoules Diameter~12 mm |

| Fricke |

UV Vis

spectrophotometer |

0.04

0.4 |

PP

vials |

|

Dichromate |

UV Vis

spectrophotometer |

1-100 |

Glass

ampoules Diameter~12 mm |

Regulatory Bodies/Standards

for gamma Sterilization facilities

Radiation sterilization process

is currently regulated by two standards, ISO 11137

and ISO13485

In India apart from

these standards CDSCO/FDA is regulating the

radiation sterilization process for health care

products according to MDR 2017

AERB (Atomic Energy Regulatory Body)-India

Medical Devices Risk Analysis ISO 14971

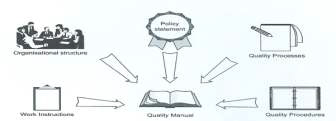

ISO 9001 (QMS)

Quality Management

System

|

RECENT DEVELOPMENTS IN

SAFETY FEATURES

What are current standards for

quality/c GMP practised by Irradiators worldwide ?

MHRA/UK

USFDA

TGA Australia

UNFPA

WHO/Drug and Cosmetic Act , India MDR 2017 / ISO

13485 / ISO 14971

ANVISA-BRAZIL

MCC- South Africa

PMDA- Japan

NMRA-Srilanka

MDA - Malaysia

ANSM-France

CDSCO India

CURRENT STATUS OF RADIATION STERILISATION

TECHNOLOGY

India largest exporter of IUDs to UNFPA

Medical Devices Act 2016 (Impending legislation)

Synergistic growth in medical devices sector

Approximately 0.175 Million Cu. M. medical

products sterilized by Gamma currently

With 23 Radiation Processing Facilities

operating in the country currently FUTURE IS

PROMISING !!

Current trend in radiation technology in

India

Captive gamma radiation facility

Contract gamma radiation facility

Capacity of each facility 1.5Mci to 5MCi

Total gamma radiation facility in India 38

Total Co-60 radiation source 38Mci as on 2023

10MeV 10kW Electron beam facility terminal

sterilization is also coming up.

Role of BRIT-DAE

Developmental initiatives with changing

trends in quality, safety and security of

industrial irradiators

Recently developed FOAK (First Of A Kind) -

animated training simulator named ISOTRAIN for

Radiation Processing Facilities

BRIT also launched ISOCAD (Integrated System of

Computer Aided Dosimetry system) A c GMP

Compliant CCPDMS

Gamma Lrradiators Worldwide

There are now about 200 commercial Co60

irradiators for radiation sterilization, operating

in 47 countries worldwide, containing

approximately 240260 MCi of gamma emitting Co- 60

Sources

Merits of gamma Sterilization

Simple Process Only parameter to control is

exposure time

Pre-packed in hermetically sealed packages,

impermeable to microorganisms, before and after

sterilization.

Temperature is not raised much: compatible with

temperaturesensitive materials, such as

pharmaceuticals and biological samples

Flexibility: can sterilize products of any

material, size, or thickness

Leaves no chemical residue

Immediate Availability of product after

sterilization

Gamma radiation easily reaches all parts of the

object to be sterilized due to its high

penetrating ability

Limitations of gamma Sterilization

Material Degradation : few material degrade

after terminal sterilization radiation dose

(brittle, colour change)

Method is costly alternative to heat

sterilization |