|

Abstract

Radiopaque barium sulphate

filled thermoplastic polymers are widely used in the

medical device industry. Barium sulphate (BaS04) is in

a group of drugs called contrast agents. Barium

sulphate works by coating the inside the stomach or

intestines which allows them to be seen more clearly

on a CT scan or other radiologic (x-ray) examination.

Barium sulphate is used to help diagnose certain

disorders of the stomach or intestines. Increasing wt%

of BaS04 with specified polymer is mixed in a twin

screw extruder. The granules of the composites thus

obtained are injection molded and tested for X-ray

opacity and it is expected that the X-ray opacity

increases with the increase in the content of BaS04 in

the polymer. Increasing the X-ray opacity in these

polymers will help to trace the medical devices in the

body and help placing them in exact location wherever

it is needed.

Keywords: Barium sulphate, X-ray opacity,

polymer, composites.

Corresponding author: Email Id

Subhasch.shit@yahoo.com ,

giripolymer@gmail.com

Introduction

A medical device is anything used for therapeutic

and/or diagnostic purposes in humans or animals, which

is not a drug. They can be classified into two

categories - disposables and nondisposables. Materials

used in design, production and assembly of medical

devices include metals, ceramics, glass and plastics.

Plastics have superior design flexibility compared to

metals, ceramics and glass. The products made from

plastics can be made into different shapes, sizes,

thickness and color to meet the physical, mechanical,

chemical and biocompatibility requirements. Plastics

can be processed by various processing techniques with

the addition of fillers and additives. One of the

requirements for medical devices used for diagnostic

and other interventional surgical

procedures is clear visibility under X-Ray. Barium

sulphate is a radiopaque additive obtained from

naturally occurring mineral known as Blanc Fixe having

an average particle size less than 2 micrometers. It

is a white powder used as a filler because of its

unique characteristics like X-Ray opacity, specific

gravity, frictional resistance, chemical resistance.

Depending on the types of applications, the criteria

for radiopacity are different. For applications near

the surface skin, devices with low radiopacity are

required but for applications like intravenous or

cardiovascular procedures, the devices have to be

inserted deep into the body and so much higher

radiopacity is required. In the application of

intravenous catheters, barium sulphate is added to the

bulk polymers to make the catheter inside the blood

vessels visible by X-Ray [1-10]. The current article

deals with making a radiopaque composite by mixing

barium sulphate as a filler with a thermoplastic

polymer with different wt% compositions of the filler

into the thermoplastic polymer matrix and preparing a

composite with different X-Ray opacities. The

composites thus prepared are tested for different

physical, mechanical, thermal and X-ray opacity tests

to decide the area of used of the final X-ray opaque

medical device.

Composites

They are combinations of two materials in which one

of the materials, called the reinforcing phase, is in

the form of fibers, sheets, or particles, and are

embedded in the other material called the matrix

phase. The matrix material can be metal, ceramic, or

polymer.

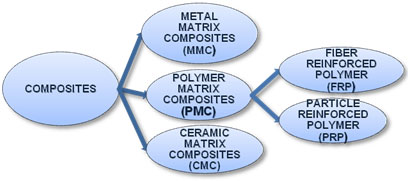

Broadly, composite materials can be classified into

three groups on the basis of matrix material.

Advantages of Composite Materials

-

Tensile

strength of composites is four to six times greater

than that of steel or aluminum.

-

Weight

savings are significant, frequently ranging from 25

to 50% of the weight savings can be achieved over

conventional metallic designs.

-

Corrosion

resistance is outstanding.

-

Good

fatigue and fracture and impact resistance.

-

Flexibility in selection or changing of styling and

product aesthetic features. Modifications in

response to changing customer needs can be made with

limited investment.

-

Like

metals, thermoplastics have indefinite shelf lives.

-

Manufacturing and assembly are simplified because of

part integration which can reduce engineering,

purchasing, and follow-up costs.

Polymer Matrix Composites

A composite in which the

matrix is either thermoplastic or thermoset polymer or

the reinforcement is in fibrous form (Glass, carbon,

aramid, natural fibers) or particulate form (Macro,

micro or nano sized particles) is called polymer

matrix composites.

Fillers

The

term filler refers to any type of low cost additive

which is used to simply increase bulk and reduce cost

of the compound additive. They are used to cheapen or

extend a product with an evident change or

modification of the properties of the unfilled

materials such as hardness, rigidity, viscosity or

color.

|